Product Id : FDB3263

Category : Food, Drugs & Biologics, Clinical & Laboratory, FDA Compliance, Medical Devices, Quality

Presenter : Carl Patterson

Scheduled On : February 10 2022 1:00 pm

US/Canada (Eastern Time - ET)

Duration : 60 Minutes

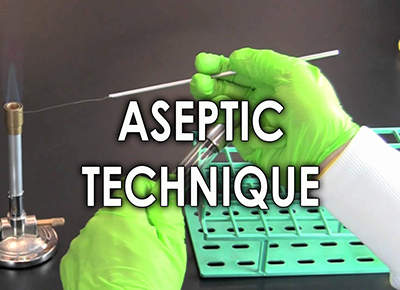

Many of the drug products manufactured for use are injected into our bodies. By avoiding our first line of defense against infection, any possible source of infection can wreak havoc on our immune systems. In order in insure our safety, these drugs must be produced aseptically, meaning with little to no source of infection.

Aseptic processing is the process by which these drugs are produced aseptically. Aseptic techniques are the principles by which aseptic processing is done.

This web seminar provides a comprehensive overview of aseptic processing and aseptic techniques.

Learning Objectives:

Provide background information on what is aseptic processing.

Understand the different methods by which drug products are rendered sterile.

Understand the controls put into place to insure product sterility

Describe the interrelationship between the components used for aseptic processing.

Describe a process flow of aseptic processing.

Areas Covered in the Session :

Definition of aseptic processing

Principles of aseptic processing

FDA guidance document on aseptic processing, September 2004

EU Annex 1, sterile manufacturing

Regulatory expectations

Definition of aseptic technique

Principles of aseptic technique

Who Should Attend:

QA/QC Departments

Contract manufacturing companies (CMOs)

Manufacturing Departments

Operations Departments

Personnel involved with aseptic processing operations

Presenter :

Carl Patterson

Carl Patterson is a seasoned Pharmaceutical Manufacturing, Aseptic Processing, and Quality Assurance Professional who is based in San Diego, California. As soon as he discovered the importance of biotechnology in the area, he was inspired to enter the pharmaceutical manufacturing industry. However, his avid interest in all things biology, microbiology, and biochemistry officially began when he served in the U.S. Army as a Preventative Medicine Specialist and a Licensed Vocational Nurse.

To date, Carl has now garnered over two decades’ worth of extensive hands-on expertise. Currently, he is the Chief Consultant of his very own consultant business called aseptic-process.net, where he specializes in the aseptic processing of pharmaceutical products in the pharmaceutical manufacturing sector. Recently, he is in the process of creating webinars so he can share pertinent information about pharmaceutical manufacturing from a microbiological perspective.

Furthermore, Carl holds various degrees and certifications, including an M.S. in Biomedical Quality Systems from San Diego State University, a B.S. in Microbiology from the University of Texas, and Specialized Certificates in QA/QC & Biotechnology from UCSD.